Why do the alloy teeth of the drill bit fall off?

- Date:2022-06-03

- Share with:

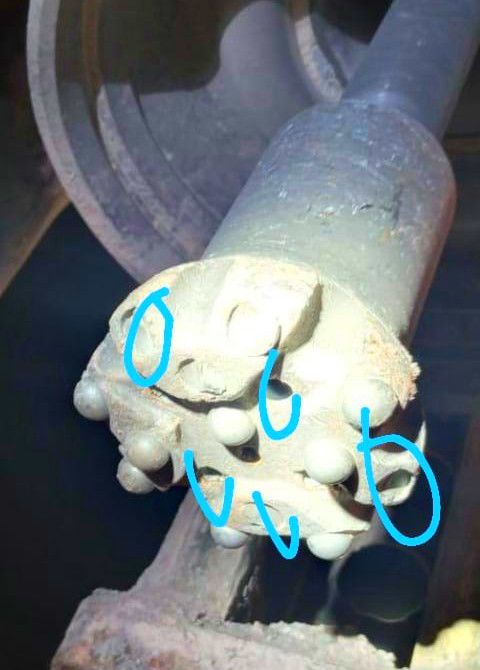

As we all know, the quality of the drill bit is very important. It can directly affect the efficiency and progress of the drilling work. I chatted with a customer Luis in South America about the quality of the drill bit yesterday. He sent me pictures of the drill bit he used before,He said that these drills kept losing their teeth and was very annoyed.

Luis said that they were fortunate to have encountered RS. Since they used the RS drill bit, their drilling work has been very smooth, the work efficiency has not only been greatly improved, but the output of the mine has also increased, and they have sent me some used drills bit picture as below.

RS hopes that the drilling work of each customer will be very smooth. Here I give you a systematic and comprehensive analysis on the loss of teeth of the drill bit. Paying attention to the situation of the drill bit during work.

Alloy teeth fall off: It is abnormal for the alloy teeth of the drill bit to fall off in the early stage. The main reasons are:

(1) Improper selection of the parameters of the tooth-fixing process or errors in the product during processing;

(2) The "empty hitting" of the drill bit product during use causes the alloy teeth to fall off;

(3) It is a process problem if it falls off before hitting a lot at the beginning; the interference fit of the inserts is improper;

(4) At the end of the hit, some of them fall off, and some do not fall, which is the problem of the width of the side teeth and the design of the valgus angle;

(5) The side teeth are not broken, and the middle teeth are broken, mainly because the design of the middle teeth is defective;

(6) The synchronous wear of the alloy and the trousers body can avoid tooth loss.

If you have meet other problems, just feel free to contact us,there is a professional technical team in our company,we will try our best to give you recommend drilling solutions .

RS rock drilling tools are widely used in different drilling applications, such as mining,quarrying, water well drilling, geotechnical industries and etc.

2.Lower energy consumption and higher impact frequency.

3.Simple structure,long life, easy and cheap maintenance.

4. Lower oil consumption.

5. Application: mining industry, metallurgy, geology, coal, water conservancy, chemical industry and road construction.

All the thread drill button bits can be equipped with rock drilling machines such as Atlas Copco, Boart Longyear, Sandvick, Ingersoll-Rand, Furukawa and so on.